Ethernet I/O Module Replace PLC I/O Card in HVAC Automation Project

Views : 14131

Update time : 2021-11-05 15:06:16

Case Study

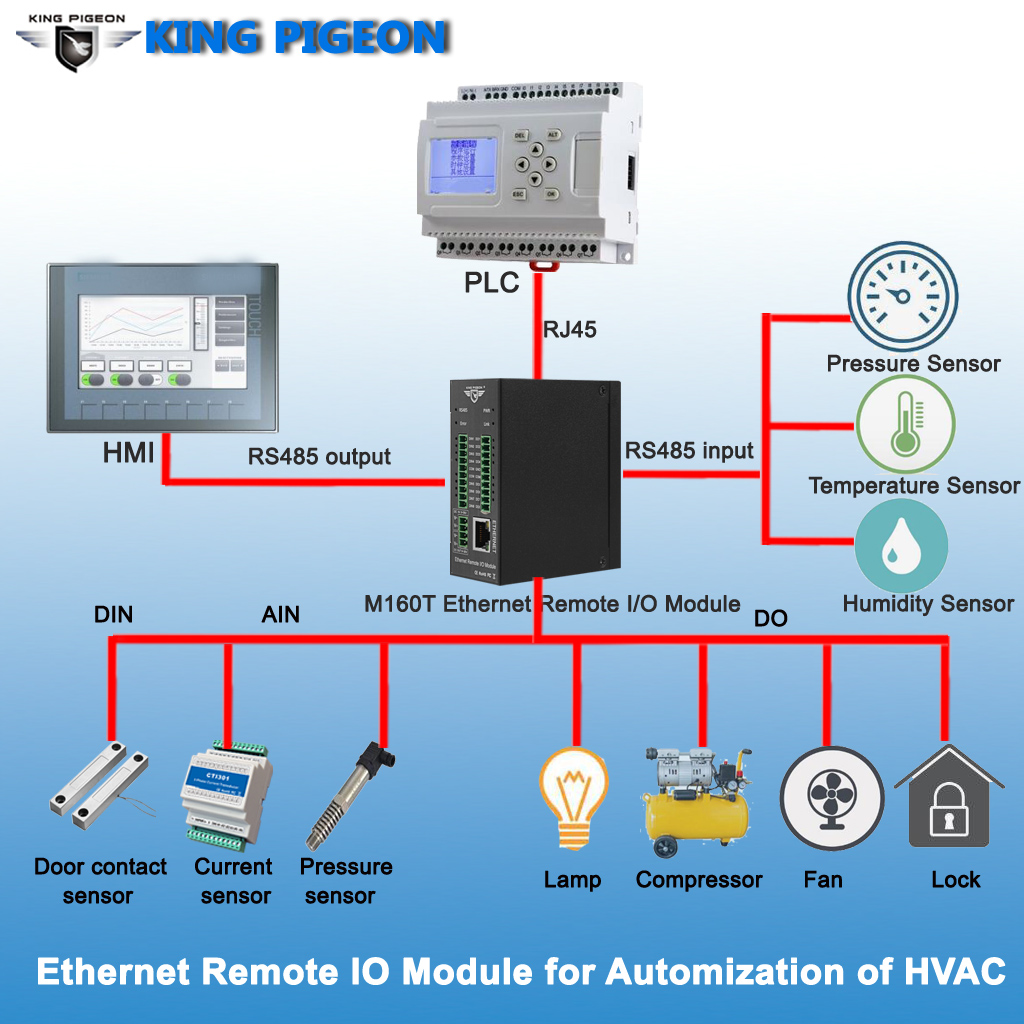

Ethernet I/O module replace I/O cards, connect PLC for building automation ( HVAC control in a clean room)

Application Scenarios Introduction

Clean rooms are widely used in pharmaceutical factories, microbiological products factories, research institute laboratories, microelectronics, semiconductors, Photovoltaic and other industries.The humidity, temperature, and airflow pressure in the clean room are very important, and need real-time monitoring, precise adjustment and control, and automatic management is essential. Therefore, the automation control of the HVAC control system is the key issue.

In this project, customer is the clean room of a pharmaceutical factory in Brazil, which uses PLC to control the HVAC system. The connection between the PLC and the field instruments is the i/o card for Wago PLC model 750-8212.

It's for a microbiology laboratory test, customer test contamination of vaccine. This company makes vaccines, serums against sneaks and spiders poison, they do R&D about drugs too.

Challenge

The customer is facing to these challenges when using the current devices:1, Cost is high

PLC needs a particular I/O card of proprietary, so the cost per I/O port is very high.WAGO PLC costs about 20 USD per Digital Output or Digital Input and 60 USD per Analog point. And the plc card is always particular, means special for wago brand only.

2, User experience is bad

PLC programming is too slow when communication, and there are conflicts to polling

Ethernet I/O Module Integrated in Solution

A Brazil company choose Ethernet I/O module M160T to substitute I/O card.The cost of Ethernet I/O module is less than USD200 but support 8 channels DI , 8 channels Analog input and 8 channels DO, therefore the average cost per I/O can reduce more than 50%.

Benefits of Using M160T Ethernet I/O Module

1, Reduce cost per I/O by more than 50%2, Simplify wiring

3, Support I/O Expansion, support more sensors/instruments/data points

4, Few conflict, communication connection more reliable

5, Better connection method. M160T support Ethernet connection , it is better over others connection that uses RS485. And It is more confiability. M160T works uninterrupted all time.

6, Only modbus map, only ID and IP. With M160T you can do only one map registers with one ID and one IP address.

PLC see only “ONE” device, only one register map for all instruments/ sensors /devices

7, Easy PLC programming. Direct access to 8AI, 8DI, 8DO, substitute for PLC card is really good!

Solution topology diagram

Customer Testimonials

With the help of solution provider who replace PLC card with M160T Ethernet I/O module, the customer pays less money on the automation of HVAC but get better clean room use experience.The user tried many solutions, such as plc card, others I/O remote, but the M160T is the best solution for them

Related News

Read More >>